In today’s competitive marketplace, speed, precision, and efficiency define the success of any manufacturing process. Companies that want to launch new products quickly, test prototypes, or keep up with customer demand must rely on technologies that reduce lead times without sacrificing quality. One such technology is fast and reliable quick turn injection molding, a process that enables businesses to produce high-quality plastic parts with remarkable speed and consistency.

This article explores why companies across industries are turning to quick turn injection molding to gain a competitive edge. With five key areas of focus, you will understand how this method not only accelerates production but also improves cost-efficiency, product quality, and long-term scalability.

The Growing Demand for Fast and Reliable Quick Turn Injection Molding

Modern businesses face increasing pressure to shorten their product development cycles. Consumers expect new products faster, and competitors are always looking for ways to deliver innovative solutions first. This shift in market dynamics has created a strong demand for fast and reliable quick turn injection molding, which allows manufacturers to drastically reduce production times. Compared to traditional manufacturing methods, this process enables companies to move from design to finished parts in just days, not weeks or months.

Additionally, quick turn injection molding is not limited to large enterprises. Small and mid-sized businesses also benefit, as it provides a cost-effective way to prototype, test, and refine their designs. With reduced lead times, companies can stay agile, respond to customer needs quickly, and make informed decisions about product launches without incurring unnecessary delays.

Speed and Efficiency in Production Cycles

One of the most significant advantages of fast and reliable quick turn injection molding is its unmatched speed in production cycles. In industries where timing can make or break a product’s success, quick turn molding ensures that businesses can manufacture parts at a rapid pace. From initial design to final part delivery, the process is streamlined, enabling businesses to stay ahead of market trends and consumer demands.

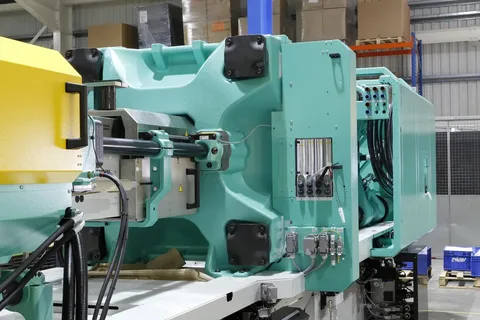

Efficiency also plays a crucial role. The use of advanced machinery and optimized processes ensures minimal downtime, maximum accuracy, and reduced material waste. Businesses no longer have to worry about extended waiting periods that slow down innovation. Instead, they can focus on scaling their production or refining their designs while the molding process delivers consistent results in record time.

Cost Savings and Resource Optimization

Beyond speed, fast and reliable quick turn injection molding offers significant cost savings. Traditional manufacturing methods often require large upfront investments in tooling and longer production runs to be cost-effective. In contrast, quick turn injection molding minimizes these expenses by enabling shorter runs with less material waste. This makes it an attractive option for companies that need flexibility and cannot commit to large production volumes upfront.

Resource optimization is another key benefit. With rapid prototyping capabilities, businesses can test multiple design iterations without breaking the bank. By detecting flaws early in the design phase, companies save resources that would otherwise be spent on rework or scrap. This lean approach ensures every dollar invested contributes to creating value, ultimately boosting profitability.

Ensuring Quality and Reliability

Quality is non-negotiable in manufacturing, and fast and reliable quick turn injection molding delivers on this front as well. Advanced techniques and precision equipment ensure that every part produced meets strict industry standards. Whether a company requires components for automotive, medical, or consumer products, quick turn molding provides consistent results with high accuracy and repeatability.

Reliability is equally important, especially when businesses are working under tight deadlines. Quick turn injection molding ensures that parts are not only produced quickly but also maintain the durability and strength required for end-use applications. This reliability helps companies maintain their reputation for delivering top-quality products while reducing the risk of defects and recalls.

Scalability and Long-Term Business Growth

For businesses planning to grow, scalability is essential. Fast and reliable quick turn injection molding supports scalability by allowing companies to start with small production runs and expand as demand increases. This flexibility means businesses can enter the market quickly, gather customer feedback, and then scale up production without facing major disruptions or costly delays.

Long-term business growth also relies on innovation, and quick turn injection molding plays a pivotal role here. By enabling rapid prototyping and fast design validation, businesses can continuously improve their products and stay ahead of the competition. This adaptability fosters a culture of innovation, ensuring that companies not only survive but thrive in a fast-paced, ever-evolving marketplace.

Conclusion

In an age where speed, quality, and adaptability are the cornerstones of success, fast and reliable quick turn injection molding has emerged as a game-changer for businesses. It empowers companies to accelerate their product development, reduce costs, ensure quality, and scale operations with ease. Whether you are a small startup or a global enterprise, adopting quick turn injection molding can significantly enhance your ability to compete and grow.

By choosing this manufacturing solution, businesses position themselves to meet customer demands quickly, innovate continuously, and achieve long-term success in an increasingly demanding marketplace.