Choosing between a timing belt and a chain drive can be tricky. Both systems do the same basic job transferring power from one part of a machine to another yet they work in very different ways. The decision often depends on the type of machinery, working conditions, and maintenance requirements. Let’s break it down in a clear, simple way so you can make an informed choice.

Understanding the Basics

Before comparing them, it helps to know how each one works.

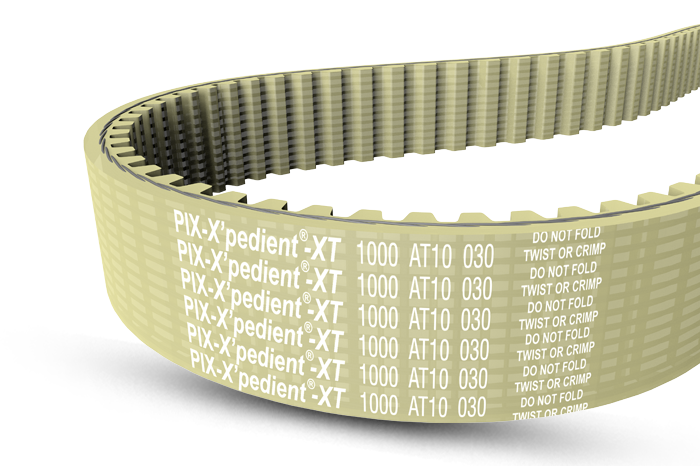

- Timing belts use rubber or polyurethane materials reinforced with fibers. They have teeth that fit precisely into the pulleys, keeping the motion perfectly synchronized.

- Chain drives, on the other hand, use metal links that rotate around sprockets. They are built for strength and can handle high torque applications.

Here’s a quick comparison overview:

| Feature | Timing Belt | Chain Drive |

|---|---|---|

| Material | Rubber, polyurethane, reinforced with fibers | Steel or metal alloy |

| Lubrication | Not required | Regular lubrication needed |

| Noise Level | Quiet | Noisy |

| Durability | Moderate | Very high |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Low | Regular and more intensive |

Note:

Selecting dependable solutions that meet the performance requirements of your machinery is crucial when looking into Timing Belts for industrial or automotive applications. To assist you in making the best decision, Pix Trans Russia provides comprehensive product details and professional guidance. For more information on appropriate solutions for your equipment, get in touch with them right now.

Performance and Efficiency

One of the main differences between the two systems lies in how efficiently they transfer power.

- Timing belts are lightweight and cause less friction, which means smoother and quieter operation. They’re also energy-efficient, making them ideal for smaller machinery and precision-based systems.

- Chain drives, on the other hand, are more durable and can handle higher loads. They’re often used in heavy-duty applications like conveyors, industrial machines, and motorcycles.

However, chain drives require regular lubrication to prevent wear. If neglected, they can become noisy and inefficient over time. Timing belts, though quieter, may wear faster if exposed to heat or oil.

Maintenance and Longevity

Maintenance is one area where timing belts clearly have an advantage. Since they don’t need lubrication, they’re cleaner and easier to handle.

But the trade-off is replacement frequency. A timing belt typically needs replacement after a certain number of hours or years of use. Chain drives, when well maintained, can last longer sometimes even outlasting the machine itself.

Here’s a maintenance comparison summary:

| Aspect | Timing Belt | Chain Drive |

|---|---|---|

| Lubrication Need | None | Frequent |

| Replacement Interval | 50,000–100,000 km (approx.) | Longer lifespan with maintenance |

| Tension Adjustment | Periodic check | Regular adjustment required |

| Environmental Resistance | Sensitive to oil and heat | Tolerant to extreme conditions |

Noise and Vibration

Noise levels may not seem like a big issue until you’re working in a quiet factory or a small workshop.

Timing belts produce little to no noise, making them ideal for applications that require smooth operation. Chain drives, however, can be loud, especially when not lubricated properly. Over time, this vibration can also lead to mechanical stress on other components.

If comfort, quietness, and low vibration matter, the timing belt wins. But for machines where durability and power come first, the chain drive holds its ground.

Cost Considerations

Initial cost is where timing belts shine. They’re cheaper to buy and install. But because they need replacement more often, their long-term cost can balance out with chain drives.

Chain drives are expensive upfront but often make up for it with durability. For large-scale operations where machines run continuously, the added cost is usually worth it.

So, Which Is Better?

There’s no one-size-fits-all answer. If your machinery requires quiet, clean, and low-maintenance operation, timing belts are the better choice. If it needs strength, long-term reliability, and can handle maintenance, chain drives are more suitable.

Think of it this way:

- Use a timing belt for smooth, precise movement.

- Choose a chain drive for heavy-duty, continuous work.

Each has its own strengths. The right pick depends on how and where you use it.

Final Thoughts

In the world of machinery, both timing belts and chain drives have earned their place. The key is not which one is universally better, but which one fits your specific needs best. With proper understanding and maintenance, both systems can deliver excellent results for years.

FAQ:

What are timing belts?

These are drive belts with internal teeth that mesh with pulleys of the corresponding profile. They ensure precise, synchronous, slip-free transmission of motion and are widely used in various mechanical systems.

Where are timing belts used?

These belts are used in automotive engines, industrial equipment, packaging and printing machines, as well as in automated systems and robotics.

What are the types of timing belts?

There are classic belts, as well as HTD and STD models. Each type is designed for a specific range of loads, speeds, and operating conditions.

How to extend the life of a timing belt?

Regularly check the belt for wear, ensure proper tension, and keep the drive mechanism clean to avoid premature failure.

Also do Read:

How to Replace a V-Ribbed Belt Like a Pro: Step-by-Step Guide

For more insightful Articles do visit mycopywatches