Every solid building starts with one choice: the blocks. Pick wisely, and you’ll have walls that last for decades. Pick poorly, and you’ll deal with cracks, wasted money, and endless repairs. Sounds dramatic? Maybe. But anyone who’s built even a small wall knows the choice of blocks makes all the difference.

Across the U.S., homeowners, contractors, and builders are all asking the same thing: Which block is best for my project? Let’s walk through the options, the factors, and the little details that matter.

Knowing the Options Before You Build

Walk into any U.S. building supply yard, and you’ll be met with a variety of blocks. They’re not interchangeable. Each one comes with a purpose.

Common Types of Blocks

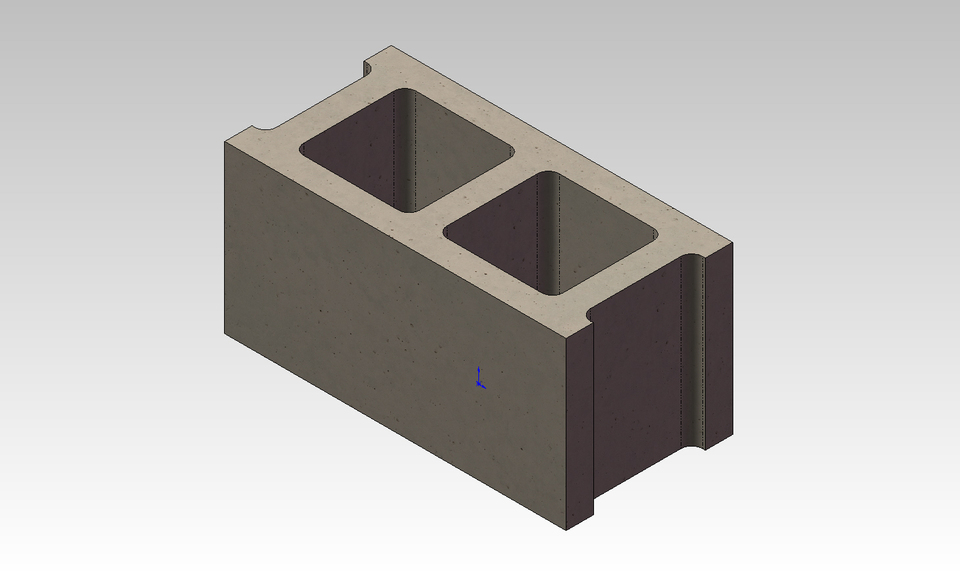

- Concrete blocks: the reliable workhorse, used for everything from basements to commercial spaces.

- Brick: timeless and classic, still shaping the streets of many East Coast cities.

- Aerated blocks: lightweight, faster to install, and energy-efficient.

- Stone veneer: often chosen for curb appeal in suburban and Midwestern homes.

Regional Preferences

- Florida: reinforced blocks for hurricanes.

- Midwest: stone veneers for stylish facades.

- Arizona: lighter materials for extreme heat.

When you’re deciding between cmu block sizes, remember that measurements aren’t just numbers. The dimensions determine how much material you’ll use, how fast the walls go up, and how sturdy the result will be.

Why Strength and Durability Matter Most

Building for Harsh Climates

Different regions test blocks in different ways. Northern winters punish blocks with freeze-thaw cycles. Western deserts bake them under constant heat.

Reinforced Options

Concrete masonry units remain popular because they’re tested, certified, and durable. Hollow blocks can be customized with insulation or steel reinforcement for extra strength.

In the U.S., quality control is strict. Groups like the American Concrete Institute certify blocks so buyers know they’re not just getting a lump of concrete, but a product designed to last.

The Cost Question: Balancing Budget and Quality

Regional Cost Differences

- California: higher labor and stricter codes push costs up.

- Midwest: local supply chains keep prices more affordable.

Smart Spending for Homeowners

For smaller projects, mid-range blocks are often enough. For large-scale builds, negotiating with suppliers makes sense—but cutting corners on quality almost always backfires.

Trusted suppliers like strand co have built their reputations by balancing affordability and reliability. That’s the kind of partner you want if you’re investing real money into a project.

Blocks That Look as Good as They Last

Aesthetic Trends Across the U.S.

Strength is important, but looks matter too. Many homeowners and businesses now want their walls to do more than just stand tall.

- West Coast: Breeze blocks bring back mid-century modern flair.

- Suburbs: Polished or tinted blocks blend with siding and landscaping.

- Commercial spaces: Split-face textures or colored masonry replace plain gray walls.

Why Curb Appeal Counts

In neighborhoods across the country, block choice can directly impact property value. People want something sturdy, but also something they’re proud to look at every day.

Sustainable and Eco-Friendly Options

The Push Toward Sustainability

Green building is no longer a trend—it’s expected. Builders and homeowners alike are asking for blocks that reduce energy use and environmental impact.

Eco-Friendly Practices

- Recycled materials mixed into block production.

- Carbon-neutral manufacturing experiments in states like Texas and Colorado.

- Blocks designed for insulation, lowering heating and cooling bills.

In some projects, certifications like LEED make eco-friendly choices a requirement rather than an option.

Local Factors That Can’t Be Ignored

Climate Makes a Difference

- Florida: hurricane-ready reinforced blocks.

- California: flexible systems for earthquake resilience.

- Minnesota: freeze-resistant designs.

- Arizona: cooling properties built into blocks.

The Role of Building Codes

Every state has its own codes and inspections. A block approved in one state might not pass in another. That’s why checking regulations before buying is essential.

Tips for DIY Homeowners

Not every block project is a skyscraper. Plenty of U.S. homeowners use blocks for backyard projects, firepits, or garden walls.

Practical Tips

- Plan drainage first. Water ruins walls quickly.

- Stick to one size. Uniformity helps stability.

- Use proper tools. Levels, compactors, and saws save headaches.

- Plan for delivery. Blocks are heavy—don’t overload a pickup.

- Ask the experts. Local suppliers know what works in your soil and climate.

Even if you’re doing the work yourself, one quick consultation with a contractor can save you a lot of trial and error.

Innovation and the Future of Masonry

Smart Blocks

New blocks with embedded sensors are being tested. They can detect cracks or stress and send alerts.

Robotics and Automation

Construction firms are beginning to use robots to lay blocks, speeding up projects while reducing labor costs.

3D Printing

Some companies are experimenting with 3D-printed concrete, reshaping what’s possible for custom structures.

Even with these advances, one fact stays the same: the success of your project depends on choosing the right blocks.

Wrapping It Up: Building Smart in the U.S.

Block selection isn’t a detail you gloss over—it’s the foundation of everything. Durability, cost, looks, sustainability, and climate all shape your decision. A retaining wall in Ohio doesn’t need the same block as a coastal home in Florida.

The best advice? Think long-term, lean on reliable suppliers, and factor in local conditions. With the right blocks, your project won’t just last—it’ll add safety, value, and pride to your property.