In today’s industries—whether oil & gas, chemical processing, or manufacturing—efficiency and purity are everything. Contaminants in liquids or gases can damage equipment, slow production, and increase costs. That’s where a coalescer comes in—a proven solution designed to remove fine liquid droplets or solid particles from process streams.

What is a Coalescer?

A coalescer is an advanced filtration device that works by combining small liquid droplets into larger ones, making separation and removal easier. It’s widely used for:

- Removing water from fuels and oils

- Eliminating mist from natural gas streams

- Enhancing separation in chemical and refining processes

- Protecting compressors, turbines, and pipelines

Simply put, coalescers safeguard your operations, ensure product purity, and cut down maintenance costs.

Types of Coalescers

Depending on your application, you can choose from:

- Liquid–Liquid Coalescers – Remove water from hydrocarbons, fuels, and lubricants.

- Gas–Liquid Coalescers – Capture aerosols, mists, and vapors from gas streams.

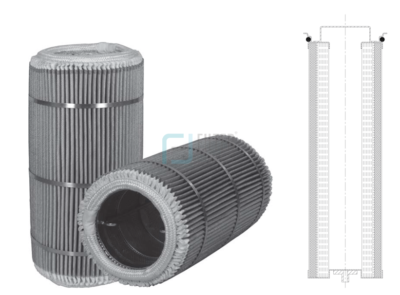

- Cartridge Coalescers – Compact designs for high-efficiency filtration.

- Panel & Vane-Type Coalescers – Ideal for large-scale industrial separation.

Why Your Business Needs a Coalescer

Investing in the right coalescer is not just about filtration—it’s about protecting your assets and maximizing uptime. Some key benefits include:

✅ Improved Efficiency – Cleaner fuels and gases lead to smoother operations.

✅ Cost Savings – Reduce equipment wear, energy losses, and maintenance costs.

✅ Regulatory Compliance – Meet strict environmental and safety standards.

✅ Extended Equipment Life – Prevent damage caused by moisture, particulates, and corrosives.

Commercial Applications of Coalescers

Coalescers play a crucial role across multiple industries:

- Oil & Gas: Separating water and contaminants from fuels, natural gas, and lubricants.

- Aviation: Ensuring jet fuels remain clean and safe.

- Power Plants: Protecting turbines and compressors.

- Pharmaceuticals & Chemicals: Enhancing purity in sensitive production lines.

- Manufacturing: Reducing downtime by keeping systems contaminant-free.

Choosing the Right Coalescer

When selecting a coalescer for your business, consider:

- Flow rate and capacity requirements

- Operating temperature and pressure

- Type of contaminants to be removed

- Compatibility with existing systems

Partnering with the right supplier ensures you get a customized coalescer solution that delivers long-term results.

Final Thoughts

In an era where efficiency and reliability are non-negotiable, a coalescer is not just a filter—it’s an investment in your business performance. By removing impurities from liquids and gases, it helps companies cut costs, improve quality, and safeguard critical equipment.

If you’re ready to take your operations to the next level, investing in a high-quality coalescer system is the smartest move you can make.