Guniting services play a vital role in construction and repair projects where strength and durability are essential. The technique involves spraying concrete or mortar at high velocity onto a surface, ensuring excellent bonding and density. Whether used for tunnels, retaining walls, bridges, or building rehabilitation, guniting ensures long-lasting structural performance. With urban infrastructure facing constant stress, guniting services have become one of the most effective solutions for repair and strengthening projects.

What is Guniting in Construction?

Guniting is the process of applying concrete or mortar pneumatically through a hose at high pressure. The material is shot directly onto the surface, forming a dense and compact layer. Unlike traditional concrete application methods, guniting allows better adhesion, even in areas that are hard to reach. This technique is widely used in structural repair, slope stabilization, and water-retaining structures. Due to its effectiveness, many construction professionals rely on guniting services for both new and old structures.

Importance of Guniting in Structural Repair

Over time, structures face challenges like cracks, water seepage, and reduced load-bearing capacity. Guniting services help restore strength without the need for major demolition or reconstruction. The high-pressure application ensures that the new layer of concrete bonds effectively with the existing surface. This makes it a cost-effective and time-saving solution compared to complete replacement. Many building owners and contractors prefer guniting for rehabilitation because it provides durability and reduces maintenance needs.

Applications of Guniting in Modern Construction

Guniting is widely used in multiple sectors of construction and infrastructure. For residential and commercial buildings, it helps in repairing columns, beams, and walls that have weakened over time. In civil engineering projects, guniting is applied to canals, dams, water tanks, and tunnels to improve water resistance and prevent leakage. Retaining walls, slopes, and embankments also benefit from guniting services as they gain added strength against soil erosion. Its versatility makes it one of the top choices in construction.

Guniting vs Shotcreting: Understanding the Difference

Many people confuse guniting with shotcreting, but there are subtle differences. Guniting generally uses dry-mix concrete, where water is added at the nozzle during spraying. Shotcreting, on the other hand, often uses a wet mix that is pumped through the hose. Both techniques provide high strength and durability, but guniting is particularly suitable for repair works where accessibility and bonding are crucial. Knowing the difference helps construction professionals choose the right method for their projects.

Benefits of Guniting Services

The advantages of guniting services go beyond just structural strength. First, it provides excellent adhesion to surfaces, ensuring that the repaired area lasts longer. Second, the dense application of concrete increases water resistance, which is essential for water tanks, dams, and underground structures. Third, guniting reduces costs by minimizing the need for complete reconstruction. Finally, it is highly flexible, making it suitable for irregular surfaces and hard-to-reach areas, where traditional concrete pouring is not feasible.

Why Guniting is Preferred for Building Rehabilitation

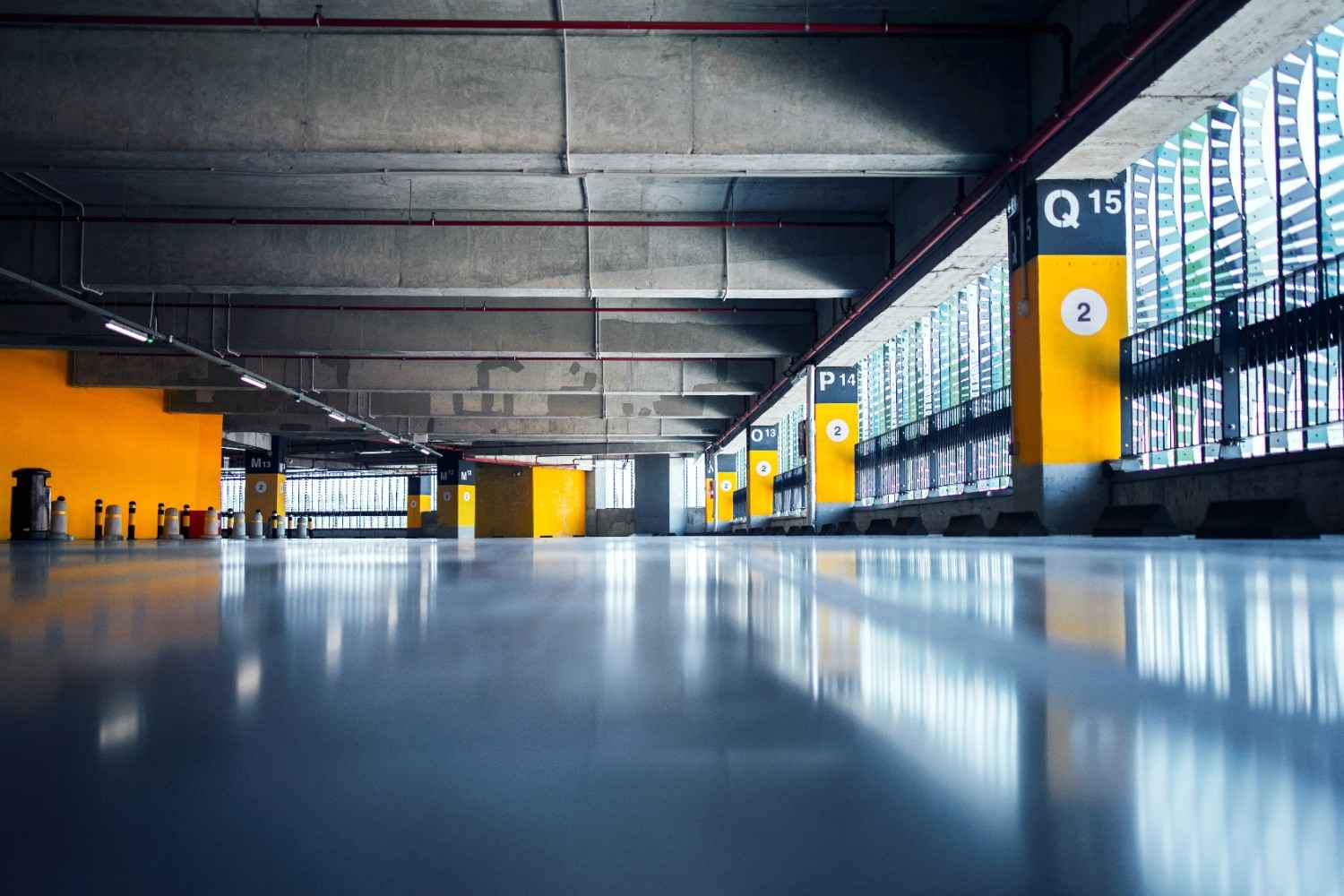

In urban cities, many old structures face deterioration due to pollution, weather, and heavy usage. Guniting services are highly effective for building rehabilitation because they can extend the lifespan of structures without significant reconstruction. For example, old residential apartments, bridges, and industrial plants often undergo guniting to restore strength. This technique is also used to address seepage problems in basements and underground parking areas. For contractors and owners, guniting ensures both safety and long-term performance.

Process of Guniting in Construction Projects

The guniting process begins with preparing the surface by cleaning and removing loose material. Once the surface is ready, the concrete or mortar mix is sprayed at high velocity using specialized equipment. The skilled nozzleman controls the spray for even distribution and proper compaction. Curing is done afterward to achieve maximum strength. The process requires expertise and precision, which is why professional guniting services are recommended for achieving the best results in any project.

Guniting for Water Retaining Structures

Water tanks, swimming pools, dams, and canals require strong, leak-proof construction. Guniting services are widely used for these projects because they ensure dense, impermeable layers of concrete that resist water penetration. Traditional concrete may leave weak spots, but guniting creates uniform coverage. This is why many contractors prefer it for water-retaining structures. Additionally, guniting is cost-effective for repairing leaks and cracks in existing tanks or pools, avoiding the need for expensive reconstruction.

Guniting for Slope Protection and Retaining Walls

Slope stabilization and retaining walls are crucial for preventing soil erosion and landslides, especially in hilly areas. Guniting services provide an effective solution by adding a strong, protective concrete layer over the soil surface. This prevents weathering and enhances stability. In retaining walls, guniting adds strength and durability to withstand pressure from soil and water. Infrastructure projects across highways and railways often rely on guniting to secure slopes and ensure long-term safety.

Guniting in Bridge and Tunnel Construction

Bridges and tunnels face constant stress from vehicles, water seepage, and environmental conditions. Guniting services help in both construction and repair of these structures. In tunnels, the sprayed concrete provides immediate support and prevents rock falls. For bridges, guniting is used to repair piers, decks, and abutments that show signs of wear. Its quick application process ensures minimal disruption to traffic, making it a preferred choice in large-scale infrastructure maintenance.

Choosing Professional Guniting Contractors

Hiring skilled and experienced contractors is crucial for the success of any guniting project. Professional guniting services ensure proper surface preparation, correct mix ratio, and accurate application. Trained workers handle the equipment to achieve uniform coverage and bonding. Before hiring, clients should check the contractor’s experience, past projects, and certifications. Choosing a reliable service provider not only guarantees quality but also ensures the safety and durability of the structure being repaired or constructed.

Guniting services are one of the most effective and reliable techniques in modern construction and repair. From water tanks and tunnels to bridges and old buildings, guniting provides lasting strength, durability, and protection against environmental factors. Its ability to restore structures without complete demolition makes it a cost-saving option for many projects. With growing urban infrastructure needs in India, professional guniting services will continue to play a key role in ensuring safe and sustainable construction.