Introduction

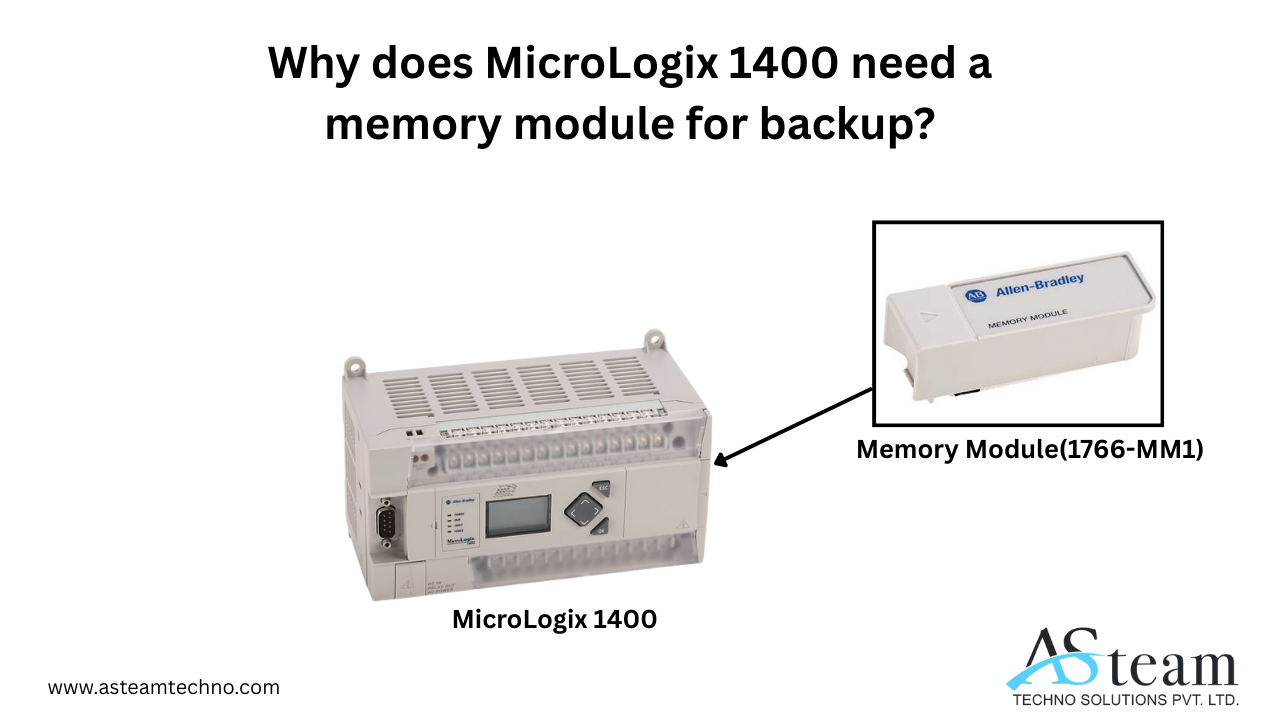

The Allen-Bradley MicroLogix 1400 (1766-L32BWA) PLC is a reliable and widely used controller in small to mid-size industrial automation systems. Known for its flexibility and built-in communication features, it plays a critical role in managing processes, controlling equipment, and ensuring smooth operation. In any industrial setup, however, protecting the PLC program and user data is just as important as running the process itself. A lost or corrupted program can bring production to a halt, resulting in costly downtime.

This leads to an important question: why is a memory module essential for the MicroLogix 1400? The answer lies in ensuring program safety, fast recovery, and long-term reliability in demanding industrial environments.

Why Backup is Necessary

Relying solely on the MicroLogix 1400’s internal memory can be risky. Power interruptions, hardware faults, or even memory corruption can cause the controller to lose its program. In such cases, recovery without a backup can take hours or even days, especially if engineers need to re-download the program using specialized software.

This is where the EEPROM-based memory module (1766-MM1) comes into play. Unlike volatile memory, which depends on constant power or a battery to retain information, an EEPROM module stores data permanently until it is overwritten. While the MicroLogix 1400 does include battery-backed RAM for temporary retention, batteries can fail over time. The memory module provides non-volatile storage, making it a much safer option for long-term program protection.

Key Functions of the Memory Module

The memory module in the MicroLogix 1400 serves several essential functions:

- Program Recovery: In the event of memory corruption, a hardware fault, or a firmware update, the program can be quickly reloaded from the memory module, minimizing downtime.

- Commissioning & Updates: OEMs and service engineers can use the module to quickly deploy standardized programs across multiple units. End-users can also restore updated programs on-site without the need for laptops or RSLogix software.

- Transportability: The memory module can be moved between controllers, making program transfer simple during replacements or system upgrades.

- Data Integrity: Unlike battery-backed RAM, the memory module ensures safe, long-term data storage, independent of power or battery status.

- User Data Backup: Any changes made to the program after commissioning can be manually backed up to the module, ensuring that site-specific adjustments are not lost.

Practical Benefits in Real-World Scenarios

The use of a memory module in MicroLogix 1400 offers several advantages in day-to-day operations:

- Quick Restart After Downtime: If a controller experiences a fault, it can be restored to its last saved state without connecting to programming software.

- Reduced Dependence on Laptops: Service engineers no longer need to carry laptops and software for simple recoveries or commissioning tasks.

- Easier Replacement: When a controller fails, the replacement can be up and running quickly by inserting the pre-loaded memory module.

- Support for OEMs: Equipment manufacturers often supply pre-programmed modules to customers, making it easier to deploy and update applications across multiple sites.

Technical Notes and Limitations

While the memory module is extremely useful, it does come with certain technical notes and limitations:

- Backup Only: The module does not increase the working RAM of the controller—it is strictly for backup and recovery.

- Potential Overwrite: Reloading from the module resets the PLC to its last saved state, which means recent site-specific changes may be lost if they weren’t saved to the module.

- Handling Practices: The module can be removed and shipped separately, but it should be handled carefully to prevent data damage.

- Backup Options: The MicroLogix 1400 provides both battery-backed RAM and an external memory module, but only the module guarantees non-volatile storage.

Best Practices for Using a Memory Module

To get the most value from the MicroLogix 1400 memory module, consider the following best practices:

- Update Regularly: Always write updated programs to the memory module after making changes in RSLogix 500.

- Label and Version Control: Keep each module clearly labeled with version numbers and dates to avoid confusion during deployment.

- Combine with Battery Management: Use the memory module alongside proper battery management for maximum reliability.

- Use with Documentation: Keep documentation of program versions and memory module contents for easier troubleshooting and scaling.

Conclusion

The MicroLogix 1400 is a versatile controller, but its reliability greatly increases with the addition of a memory module for backup. From safeguarding programs against corruption to simplifying commissioning and system recovery, the module ensures smoother operations and reduced downtime. By adopting best practices such as regular updates, safe handling, and version tracking, users can unlock the full benefits of this essential accessory. In today’s demanding industrial environments, a memory module is not just an add-on—it’s a necessity.

FAQs

Q1. Does the MicroLogix 1400 work without a memory module?

Yes, the controller can function without one, but the memory module ensures you have a reliable backup in case of program loss, making recovery much faster and safer.

Q2. How do I update the memory module in MicroLogix 1400?

After editing the PLC program in RSLogix 500, you must manually write the updated program to the memory module to keep it synchronized with the latest changes.

Q3. Can the memory module be reused across different MicroLogix 1400 units?

Yes, the same module can be moved between compatible units, which makes it extremely useful for commissioning new systems or replacing failed controllers.

Reach Us

Asteam Techno Solutions Pvt. Ltd. is AVEVA (Formerly Wonderware) Registered System Integrator providing sale/service/support and executing the HMI/SCADA, Historian/MES Solutions to End-user & OEM/System Integrator community for their diverse needs.

Leading single-source supplier & solution provider for industrial automation hardware and software solutions needed.