Custom playing card boxes are not mere packaging but a cocoon, a preserve, and give an added flavor to the entire playing card. To brands and retailers, quality testing can make these boxes durable, appealing to look at, and efficient in use. Manufacturers have to comply with stringent testing documentation to ensure every sample has the same outcome, considering that there are limitless possibilities to choose different materials, finishes, as well as printing.

Carefully assessing every part of the production process, including the choice of materials, printing longevity, businesses can gain satisfaction from their customers and increase brand trust. In the article, we will find out the necessary testing procedures that maintain the custom playing card packaging market-ready and reliable.

Material Strength Rating

Quality custom playing card boxes came into being on the basis of the strength of the material. Be it Kraft playing card boxes or cardboard playing card boxes, the raw material should go through stress tests to gauge values of bending resistance, tearing, and crushing. One of the mechanisms is to subject tensile strength testing, a measure that tests the strength of a product during transportation and handling. Such packaging will damage the cards in the event of moderate pressure. Thus, regular material inspection is done to ensure the structure is strong enough to withstand storage, stacking, and transportation difficulties without undermining the contents.

Checking of Printing Quality

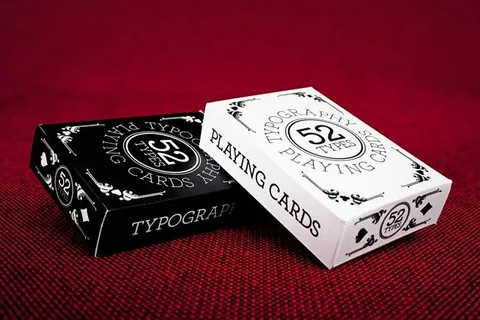

The appearance of the playing card boxes plays an important role in what makes custom printed playing card boxes competitive. Testing, emphasizing color accuracy, sharpness, and total print alignment, is done. With results being compared against the design proofs, manufacturers are able to spot problems like faded colors, pixelated text, or mislaid graphics. Further Rub resistance test guarantees that the designs on the prints can withstand handling. In the cases where companies choose playing card boxes with logos or intricate designs, these checks ensure that there remains uniformity between the logos. Proper printing not only makes the item look good on the shelves but also gives a long-term impression of reliability and professionalism.

Adhesive and Joint Testing

The quality of the adhesives, which are applied in custom playing card packaging, also has a direct effect on the integrity of the box. When bonding is enfeebled at the joints, seams, or flaps, it may cause a box deformation and dissatisfaction of customers. Producers use peel tests and shear strength to ascertain the performance of adhesives that remain functional under pressure. Exposure to heat and humidity is also used to test the softening or loss of grip of glues with time. Good stickiness will help sustain playing card boxes in use. These components are to be appropriately tested to ensure the desired durability to avoid any future replenishments or complaints due to poor assembly.

Compression and Load Testing

Packaging boxes of playing cards are frequently subjected to stacking when in storage or among the products on sale to buyers. Compression testing evaluates the load-bearing capacity of boxes to rule out exterior pressure on the box. As an example, boxes of playing cards made of cardboard go through a test of their resistance to pressure to find out at what weight they can resist collapse. This measure helps the packaging deal with the situation without bending or reshaping its products during shipment or in the warehouse stacking. For brands selling custom laying card boxes wholesale, it is important to ensure consistency in the load resistance of batches. This test indicates structural robustness and helps customers to be reassured of the best packaging performance.

Environmental Resistance Checks

Boxes used to package the playing cards have to be able to withstand storage and transportation in different environments. Examples of testing are subjecting packaging to temperature change, moisture, and light exposure. Playing card boxes manufactured by Kraft are tested to see how well they absorb moisture without warping or softening. UV resistance is a test to find out how long printed surfaces withstand flaws in continuous exposure to light. The checks give assurance that the boxes will stay in shape and look presentable, irrespective of the weather or storage conditions. The ability to perform consistently under conditions ensures the credibility of brands without causing damage in the long run to the packaging, as well as the playing cards included.

Functional Design Evaluation

A quality custom playing card box should not just be strong but also useful. Features that the design is evaluated according to include opening easily, closing smoothly, and usability as a whole. The design of playing card boxes with a window is tested further to make sure that transparency films do not scratch, fog, or peel over time. Custom playing card box customer experience is also reviewed- Is the customer able to fit the card box in his hand comfortably, and does he have accessibility to the card box? In investigating these concepts of usability, the manufacturers ensure that the packaging integrates both the aesthetics and functionality, ty and thus the product will be attractive even to the casual gamers and to the collectors.

Safety and Compliance Testing

There is a role of safety when printing custom playcardards packaging. Compliance testing: It establishes that inks, adhesives, as well as coatings that are involved during production comply with safety requirements. Environmentally friendly and even non-toxic materials are in focus, especially those kraft playing card boxes that are positioned as eco-friendly alternatives. Nick points, sharp edges, maintenance of free-moving parts, or unstable ends are tested to avoid consumer injuries. Furthermore, the products that are shipped to the international market need to satisfy the safety certifications of the region. Complying with compliance regulations precisely will lead manufacturers to the prevention of expensive product recalls and the growth of customer confidence in their choices of packaging solutions.

Consumer Usability Tests

As well as technical tests, physical tests by consumers in usability situations give the necessary comments on the packaging performance. Such testings comprise the provision of custom printed playing card boxes to focus groups, so they could do some practical testing. Comfort, ease of opening, and durability, which come out in repeated useare tested with the participants. The feedback is used to improve design decisions, which should be customer-friendly in terms of packaging. The cross-market expectations, in the case of marketing brands that manufacture playing card boxes with a logo or custom printed candle boxes as products in a broader line, are indexed in such trials. Consumers can be used to shape final packaging by using consumer insight so that packaging appeals to buyers, leads to greater satisfaction, and to better brand loyalty.

Conclusion

Custom playing card boxes have to go through a strenuous testing process to make them last long, beautiful, and practical. Whether it is being tested on material strength or put through consumer usability trials, each of these processes ensures that the packaging is reliable and has aesthetic appeal. With these testing procedures, manufacturers lower risks, strengthen their brand image, and can satisfy their customers regularly. pkv007

In the modern world, where every other company is struggling to hit the competitive edge, quality levels cannot be ignored in custom playing card packaging, and this is necessary to stay in business in the long run. Eventually, paying off to take the test will pay off as the custom playing card boxes emerge as both protective and highly aesthetic products.