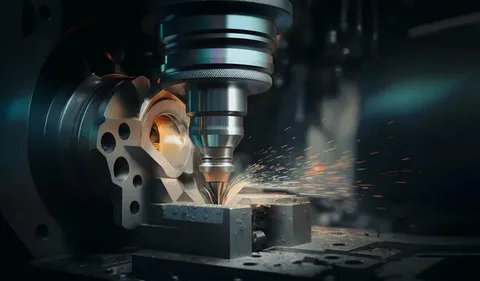

CNC machining services have revolutionized manufacturing across multiple industries by providing unmatched precision, efficiency, and flexibility. From medical devices to electronic components and heavy industrial machinery, CNC machining allows manufacturers to produce parts with exact specifications and tight tolerances. These services utilize computer-controlled machines to cut, shape, and finish materials such as metals, plastics, and composites, ensuring consistent quality and reliability. With the growing demand for high-performance products in healthcare, electronics, and industrial sectors, CNC machining services have become essential for meeting rigorous production standards.

Moreover, CNC machining reduces human error and accelerates production timelines, which is critical in industries where quality and timing are crucial. The ability to automate complex designs and repeat processes with consistent results makes CNC machining services an invaluable solution for businesses seeking to stay competitive. Whether producing delicate surgical instruments, intricate electronic circuits, or durable industrial components, these services combine technological innovation with precision engineering, delivering superior products across diverse applications.

CNC Machining Services in the Medical Industry

The medical industry demands high-precision components that meet strict regulatory standards, making CNC machining services a perfect fit. Surgical instruments, orthopedic implants, dental prosthetics, and diagnostic equipment require micron-level accuracy to ensure safety and effectiveness. CNC machining provides the capability to produce these complex parts from biocompatible materials like stainless steel, titanium, and medical-grade plastics. This ensures that each component meets the necessary functional and structural requirements, helping healthcare providers deliver reliable patient care.

Additionally, CNC machining services allow for rapid prototyping in medical device development, enabling manufacturers to test and refine designs before full-scale production. This flexibility is crucial when innovating new medical technologies or customizing patient-specific implants. By combining precision, consistency, and speed, CNC machining services help medical manufacturers reduce costs, maintain regulatory compliance, and accelerate time-to-market for life-saving products.

CNC Machining Services for Electronics Manufacturing

In the electronics sector, components are often small, delicate, and highly intricate, necessitating advanced manufacturing techniques like CNC machining. Printed circuit boards (PCBs), housings, connectors, and heat sinks are commonly produced using CNC processes to ensure precise dimensions and tight tolerances. These services enable manufacturers to maintain consistent quality and functionality in every unit, which is crucial for electronics that rely on exact specifications for optimal performance.

CNC machining services also support innovation in the electronics industry by allowing for rapid prototyping of new devices. Engineers can quickly produce multiple design iterations to test functionality and optimize performance before committing to large-scale production. Furthermore, CNC machining accommodates a wide range of materials, including aluminum, copper, and high-performance plastics, ensuring that electronic components meet both thermal and structural requirements. The versatility and precision of CNC machining make it an essential tool for producing reliable and high-quality electronics.

CNC Machining Services in Industrial Applications

Industrial machinery and equipment require robust components that can withstand heavy use, high stress, and extreme conditions. CNC machining services provide the precision and durability needed to manufacture gears, shafts, valves, and custom fittings for industrial applications. By producing components with tight tolerances, CNC machining ensures the smooth operation of machinery and minimizes the risk of failure, which is critical for maintaining production efficiency and safety in industrial settings.

Another advantage of CNC machining services in industrial applications is the ability to handle complex geometries and large-scale production runs. From prototype parts to full-scale manufacturing, CNC machines can consistently produce components to exact specifications. This reduces downtime, improves operational efficiency, and allows industrial companies to meet demanding production schedules. Whether it’s aerospace components, automotive parts, or heavy machinery, CNC machining services provide the reliability and accuracy necessary for industrial excellence.

Advantages of CNC Machining Services Across Industries

One of the primary advantages of CNC machining services is the unparalleled precision they offer. Unlike manual machining, CNC processes are computer-controlled, which eliminates human error and ensures that each component matches design specifications. This precision is vital for industries like medical, electronics, and industrial manufacturing, where even minor deviations can result in product failure or safety issues. Additionally, CNC machining allows for complex designs that would be difficult or impossible to achieve manually, expanding the possibilities for innovation.

CNC machining services also provide significant cost and time savings. Automated processes reduce labor costs, minimize material waste, and accelerate production timelines. Industries that require rapid prototyping, small-batch manufacturing, or high-volume production benefit from the scalability and efficiency of CNC machining. Moreover, the repeatability of CNC processes ensures consistent quality across every batch, building reliability and trust with clients. These advantages make CNC machining a cornerstone of modern manufacturing practices across multiple sectors.

Future Trends in CNC Machining Services

The future of CNC machining services is closely tied to advancements in technology, including automation, artificial intelligence, and advanced materials. Smart CNC machines equipped with AI can optimize cutting paths, detect errors in real time, and even predict maintenance needs, further improving efficiency and precision. Additionally, the integration of additive manufacturing with CNC machining is enabling hybrid production processes that combine subtractive and additive techniques for even more complex and customized components.

Sustainability is another emerging trend in CNC machining services. Manufacturers are increasingly focusing on energy-efficient machines, recyclable materials, and waste reduction strategies to minimize environmental impact. This aligns with global trends toward greener manufacturing practices while maintaining the high precision and quality standards required by medical, electronics, and industrial sectors. As technology continues to evolve, CNC machining services will remain at the forefront of manufacturing innovation, delivering solutions that are faster, smarter, and more sustainable.

Conclusion

CNC machining services have become indispensable across medical, electronics, and industrial applications. They provide precision, efficiency, and flexibility that traditional manufacturing methods cannot match. From producing life-saving medical devices to intricate electronic components and durable industrial parts, CNC machining ensures consistent quality and accelerates innovation. As technology continues to advance, CNC machining services will play an even more critical role in shaping the future of manufacturing, offering industries the tools they need to stay competitive, meet regulatory standards, and deliver high-quality products.